News Story

U.S. Air Force Invests Over $1.2M in Electron Microscopy Research Initiatives

The United States Air Force Office of Scientific Research is investing more than $1.2M in electron microscopy research to advance high temperature aerial vehicle materials and novel chemical processes for patterning nanomaterials.

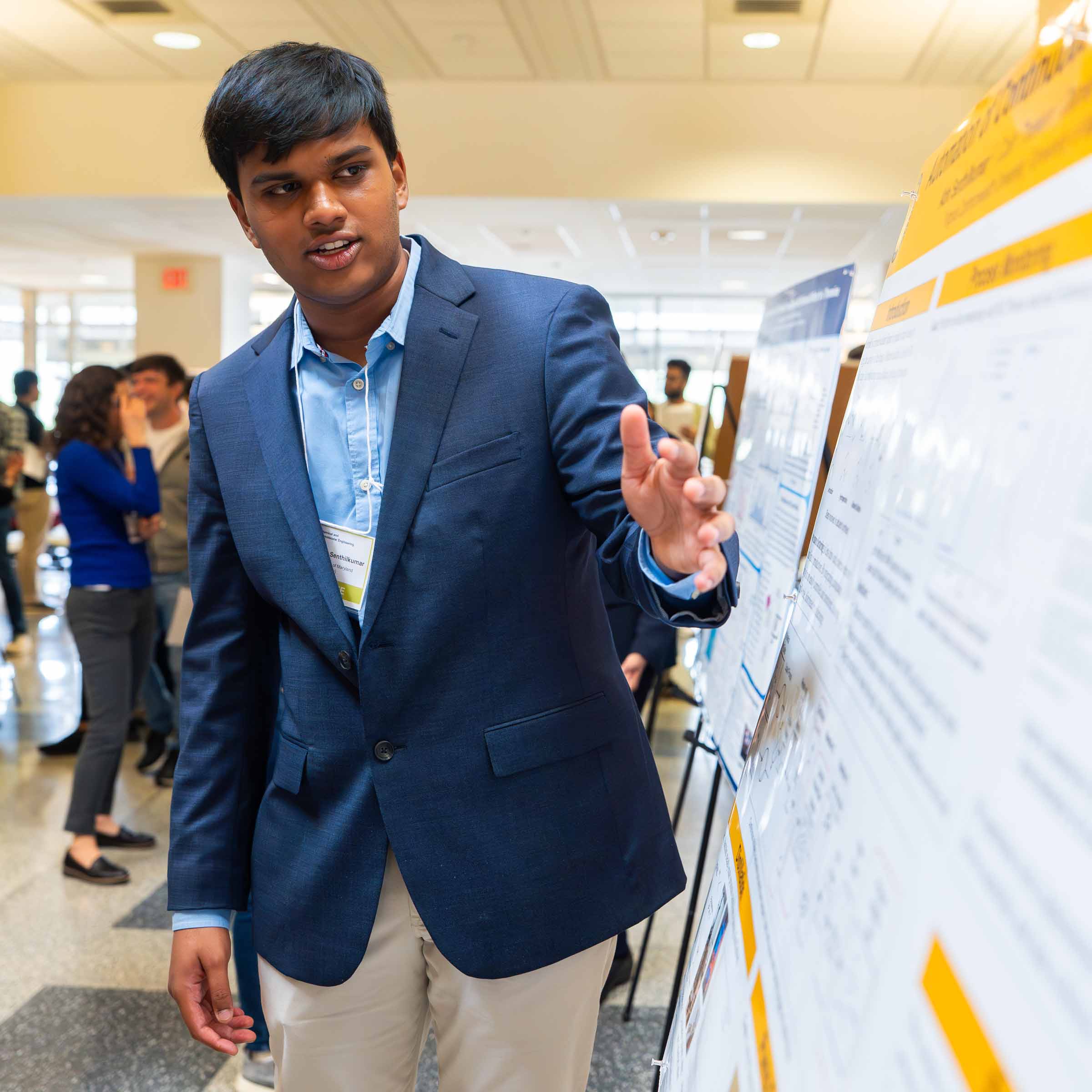

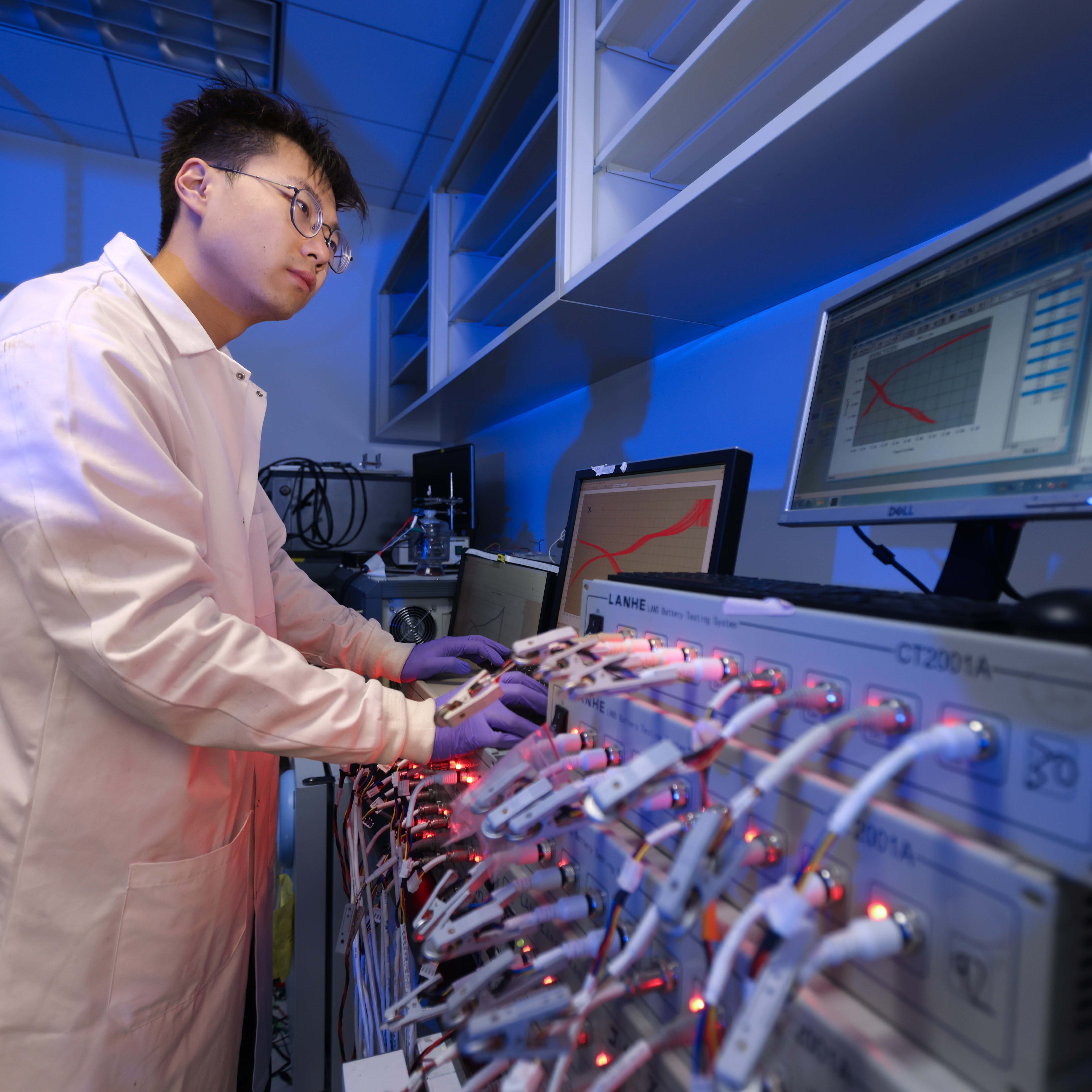

Two projects led by Taylor Woehl, an associate professor in the Department of Chemical and Biomolecular Engineering, will leverage his expertise in using electron microscopy to directly visualize chemical phenomena in liquids and gasses at the atomic scale. His goal is to solve fundamental scientific problems that currently prevent widespread application of new technologies in aerospace materials.

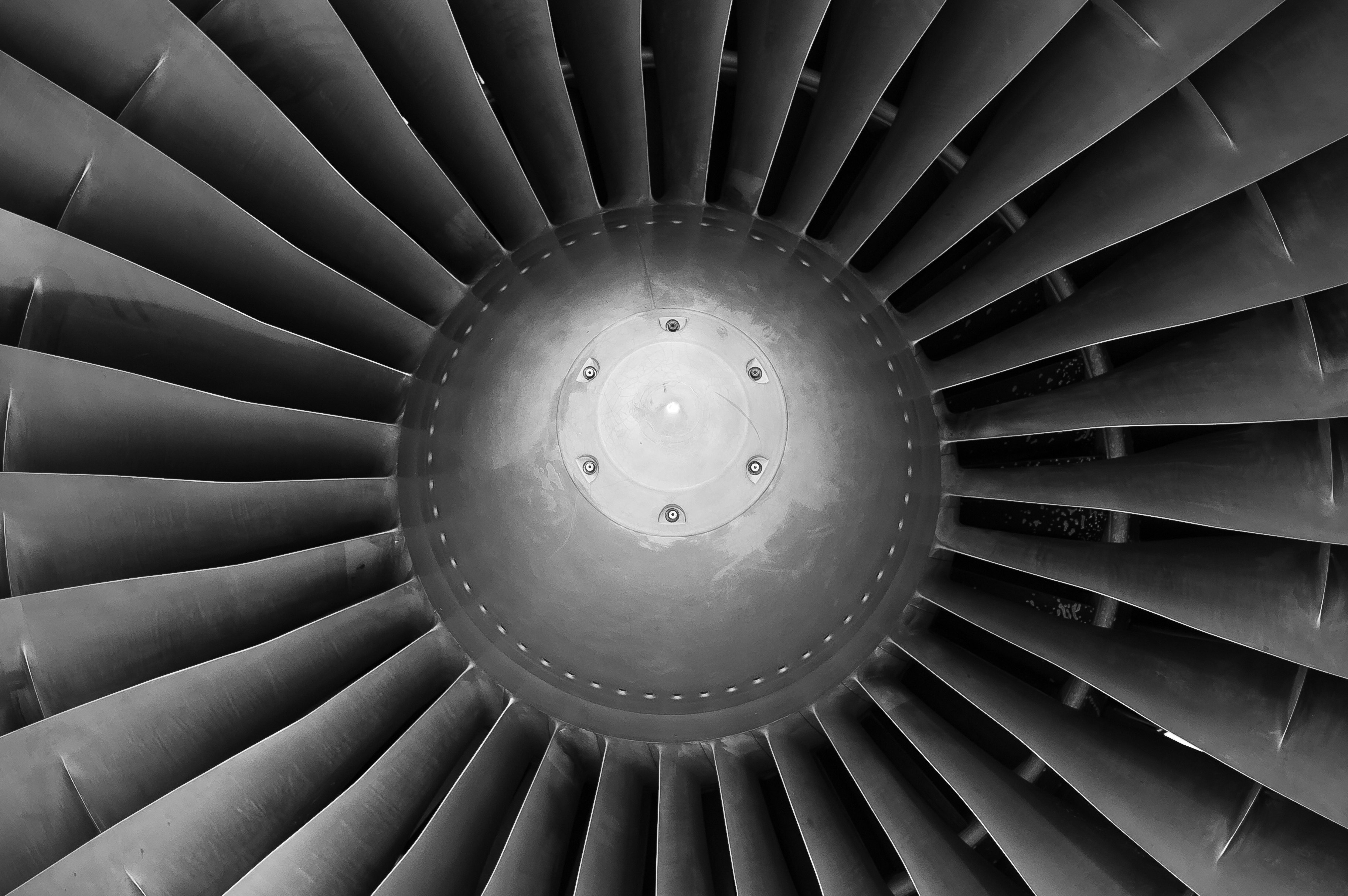

The first project will investigate an unconventional type of ceramics, high temperature and corrosion resistant materials, known as polymer derived ceramics. Advances in this field will allow for new ways to fabricate thin coating materials used in jet engines—protecting them from combustion heat and corrosion.

To replace conventional ceramics, which lack flexibility for surface coating, Woehl’s team investigates a process known as pyrolysis, in which polymers are heated at temperatures of about 2,000 degrees Fahrenheit. During this stage, the ceramics are assembled when the metals within the polymers (such as silicon, aluminum and zirconium), bond together with carbon, a common component in these materials, producing a glass-type material that can withstand temperatures up to 3,500 degrees Fahrenheit.

At the core of these promising polymer-derived ceramics, the challenge remains to uncover how they come to be. Research conducted by Woehl’s team seeks to explain how pyrolysis, the process in which these metals bond when exposed to heat, occurs to form the ceramics. His team will observe these mechanisms using advanced electron microscopy, with the goal to establish the fundamental chemistry of pyrolysis needed to rationally design new polymer ceramics with tailored properties.

“Currently, there are few design rules for tuning the polymer and processing to modify the ceramic properties; It’s like trial and error,” said Woehl. “If we can understand the fundamental chemistry of what’s happening while we pyrolyze these polymers, then we can use this understanding to rationally design better ceramics and coatings with higher operating temperatures,” said Woehl.

A second project funded by the Air Force will also involve electron microscopy techniques to observe how nanomaterials arrange into patterns by replicating a naturally occurring process observed in animals and humans called reaction-diffusion instability.

The development of fingerprint patterns in human beings and pigmentation patterns on animals, termed ‘Turing patterns,’ have been linked to a mathematical theory of reaction-diffusion instability initially proposed by Alan Turing, among others. This theory provides a mathematical framework for how biology forms asymmetric and intricate patterns during morphogenesis of embryos. While Turing patterns have been observed in biological systems and a few synthetic chemical reaction systems, these types of patterns have not been observed in nanomaterial systems. Woehl’s lab has demonstrated that nanoparticles coated onto a surface of organic molecules called siloxanes will undergo spontaneous pattern formation when the molecules are polymerized. The objective of this project is to utilize advanced electron microscopy and numerical reaction modeling to establish the chemical processes that control the emergence of nanoscale patterns.

One application of using reaction diffusion instability for nanomaterial patterning could be in optical and electronic devices. Traditional techniques used to pattern nanomaterials employ pattern templates, such as photolithography, which uses light to pattern nanomaterials into devices such as computing and photonic chips. Woehl’s team could be the first in proving that Turing’s theory could work in the context of nanomaterials and could open new doors to different modes of nanomaterial assembly and patterning that don’t rely on complex techniques.

Published November 14, 2024