News Story

Chemical Engineers Design Sustainable Hydrogen Purification Devices

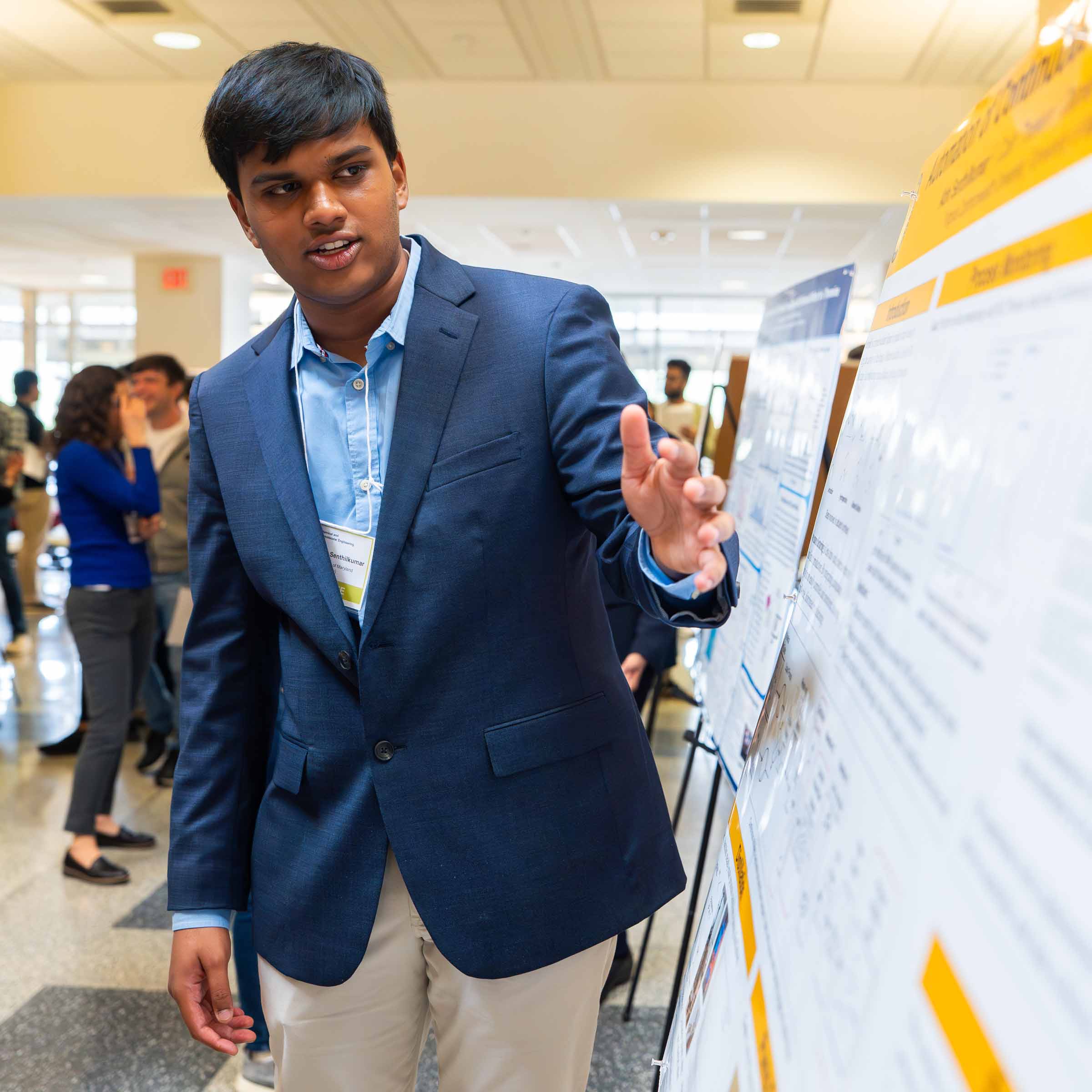

Researchers in the Department of Chemical and Biomolecular Engineering have developed a technology that could reduce the carbon footprint of the hydrogen industry.

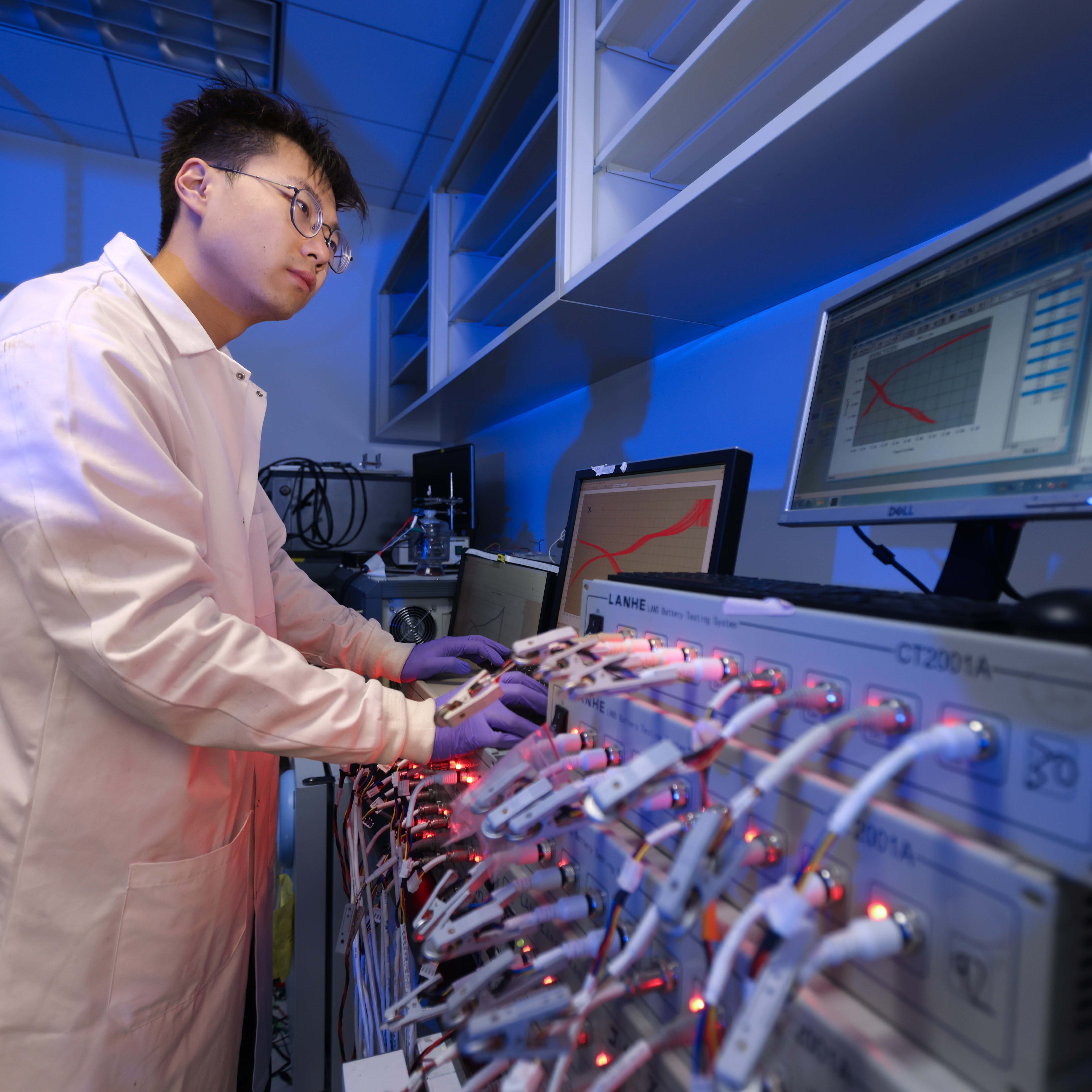

In a new paper published Wednesday in the journal Science Advances, Assistant Professor Chen Zhang led the development of a new technology for hydrogen purification that can reduce carbon dioxide emissions of current production processes. The device—a semi-permeable carbon molecular sieve membrane—purifies hydrogen produced from natural gas in a less-costly and energy efficient way.

Hydrogen, now emerging as a renewable fuel, is produced at about 10 million metric tons each year, 95% of which is derived from natural gas reforming, according to the Department of Energy. In this process, high-temperature steam reacts with methane to produce hydrogen, carbon monoxide and a smaller amount of carbon dioxide. A secondary reaction between carbon monoxide and steam then produces carbon dioxide and additional hydrogen—a gas stream that is lastly purified to contain almost entirely hydrogen. The hydrogen purification is conventionally done by processes that consume lots of energy such as adsorption and distillation at very low temperatures. These reaction and purification processes were estimated to emit 920 million tons of carbon dioxide into the atmosphere in 2023, according to data from the International Energy Agency.

Unlike conventional purification methods, the membrane developed by Zhang’s research team will allow the purification of hydrogen in a single step—consuming less energy and generating lower carbon dioxide emissions. The membrane achieves this by allowing hydrogen to pass through the membrane at least several thousand times faster than other impurities leveraging the membrane’s very tiny pores smaller than one third of a nanometer.

“The chemical industry is carbon-dioxide intensive; this new technology would reduce the carbon footprint of traditional hydrogen purification processes,” said Zhang.

Zhang’s research team, which is supported by grants from the DOE Office of Energy Efficiency and Renewable Energy and the National Science Foundation, filed a patent application and has plans of commercializing the new technology.

Published June 6, 2025