News Story

How Microscopic Metals Could Shift Catalysts Production

A new synthesis of materials smaller than a human cell could change catalyst production methods: decreasing energy and industrial manufacturing costs while incorporating new functionalities, a new study published in Advanced Functional Materials found.

Microscopic metals, scientifically known as “nanometals,” have been studied for their capacity to embed new properties into industrially available materials (such as graphene). For years, methods were unsatisfactory in combining the two without disrupting their individual properties, but today, a new method proposed by Po-Yen Chen, an assistant professor in the Department of Chemical and Biomolecular Engineering, could have uncovered the answer.

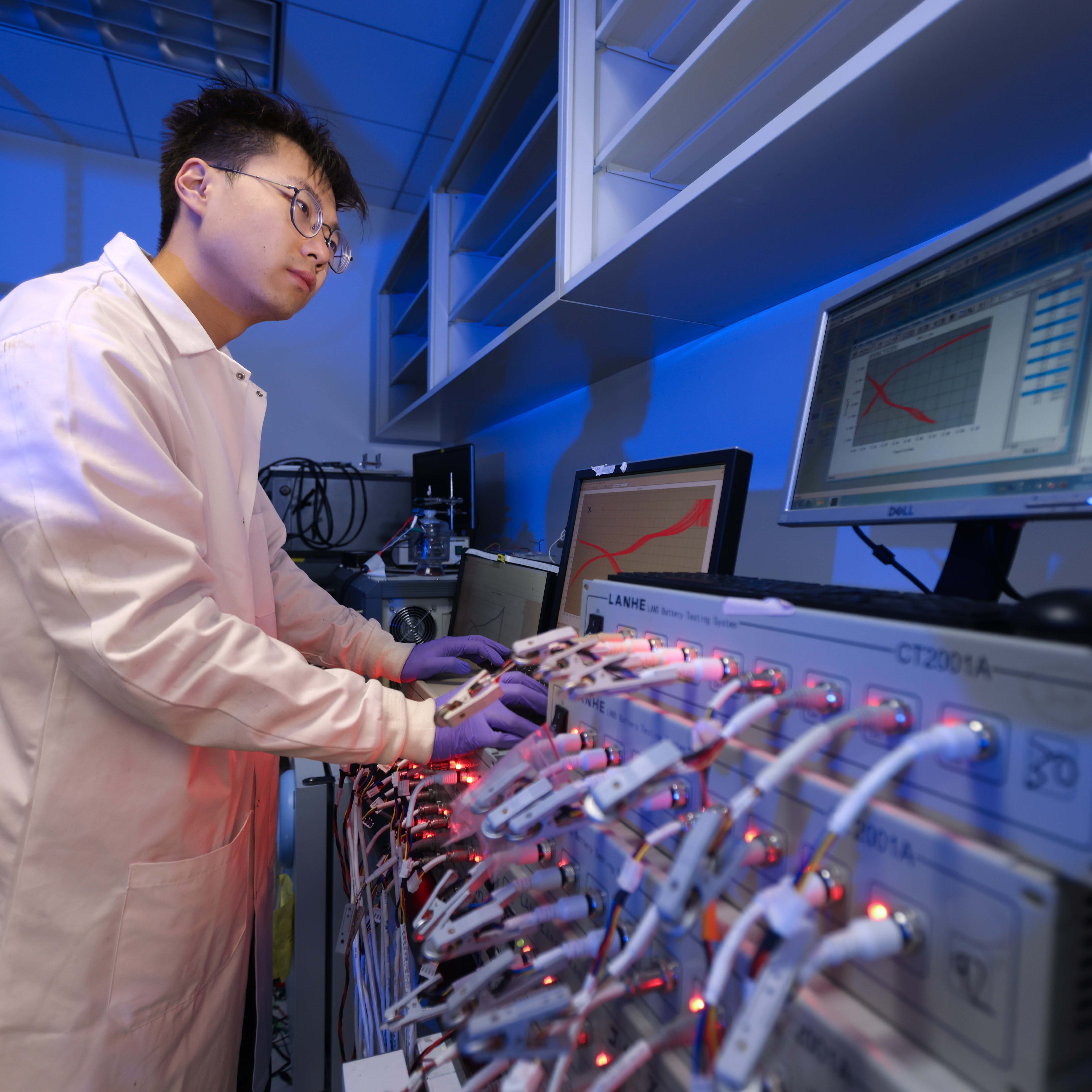

To address the limitations of conventional nanometal synthesis methods, which often negate the advantages of nanometals, the research team developed a novel process for fabricating films that allow precise control over the size, shape, distribution, and loading of nanometals. This was accomplished through a filtration technique where a gel is formed, dried, and thermally treated to facilitate nanometal growth within a nano-confined space, similar to a mold.

This filtration technique presented a new fabrication of materials that combined low dimensional nanometals, such as single metal atoms and 2D metal nanosheets, with widely used 2D materials to develop “heterostructured materials.”

These approaches introduced new chemical properties into the heterostructured materials, enhancing their electrical conductivity and catalytic activity. This improved their ability to efficiently facilitate chemical reactions, such as plastic decomposition and ammonia synthesis.

“By using the nanoconfined space of 2D materials and controlling synthetic conditions, we can create a new class of low-dimensional nanometal–2D material heterostructures. These structures show enhanced catalytic and electrochemical properties that enable more sustainable chemical production,” said Chen.

Researchers chose to work with platinum, a desirable metal for its ability to assist chemical reactions, as it is commonly used in catalysts for chemical processing industries. The results of their work presented a new alternative that could transform heterostructure manufacturing in the long term.

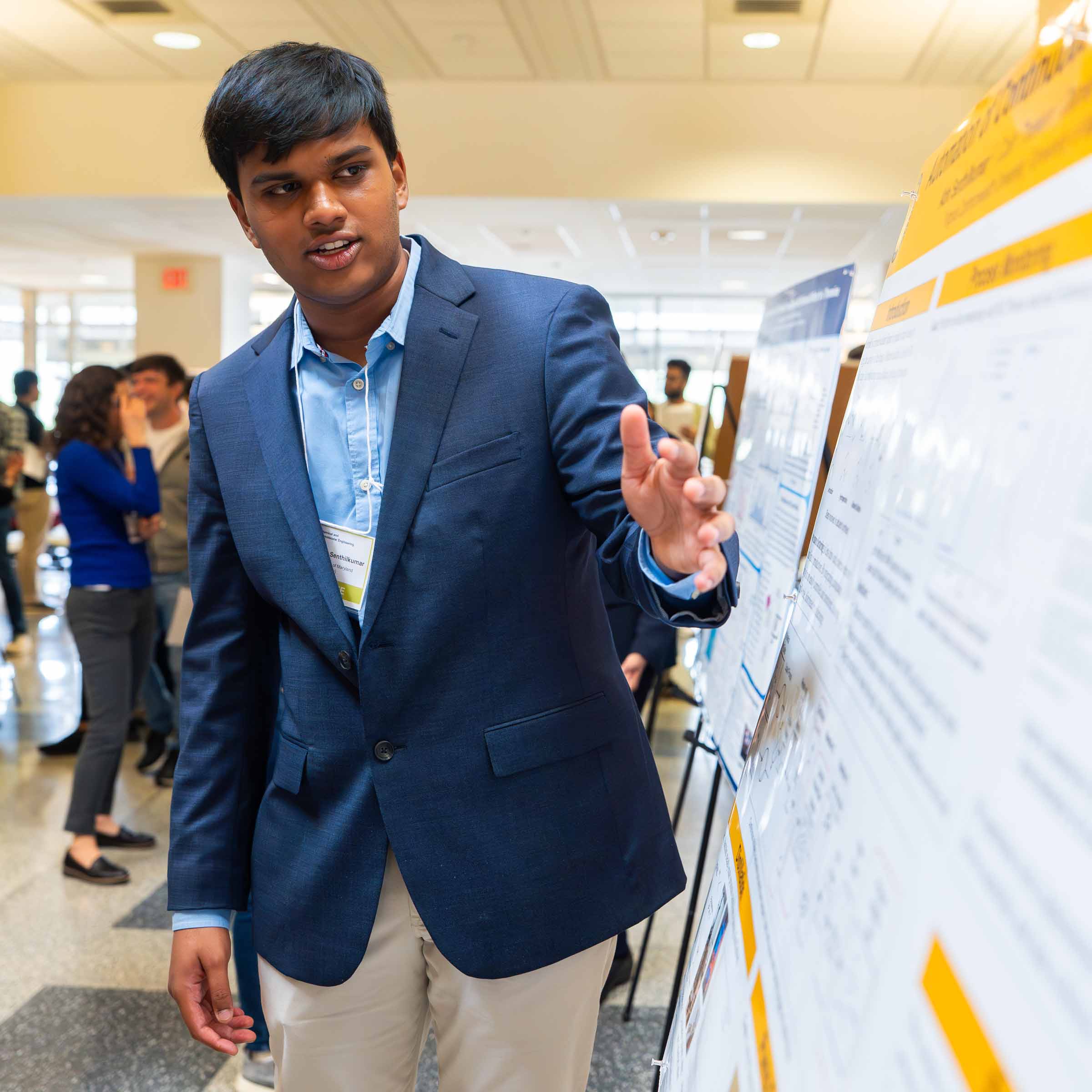

“Current rare metals used in industrial catalysts could be utilized more efficiently by optimizing their shape and size. This approach has the potential to save energy and reduce industrial manufacturing costs by millions of dollars,” said Joshua Little, a doctoral student who conducted the catalyst engineering analyses for this paper.

Although this was the first reported case of a successful controlled assembly of nanometals for heterostructures, the research group had published other findings on metal-material surface interactions. They focused on the assembly of 2D nanomaterials into large structures through noble metal ions and observed how nanometals grew on different nanomaterials (ex: clay, graphene, titanium carbide). These efforts culminated in the development of novel printable inks and 2D catalysts earlier last year.

Other researchers of this multidisciplinary effort to advance applications for low dimensional nanometals include chemical and biomolecular engineering Associate Professor Taylor Woehl, mechanical engineering Professor Siddhartha Das and University of Delaware’s chemical and biomolecular engineering Professor Dongxia Liu.

Published December 18, 2024