News Story

Automating Wearable Electronics Design: How Next-Generation Devices Could Be Engineered by AI

New advances in soft robotics and wearable devices have established a need for stretchable electronic components that can withstand mechanical deformation while sustaining their optimal performance. But engineering flexible electrodes, key to these devices, is a long-standing research challenge slowing progress for more innovations.

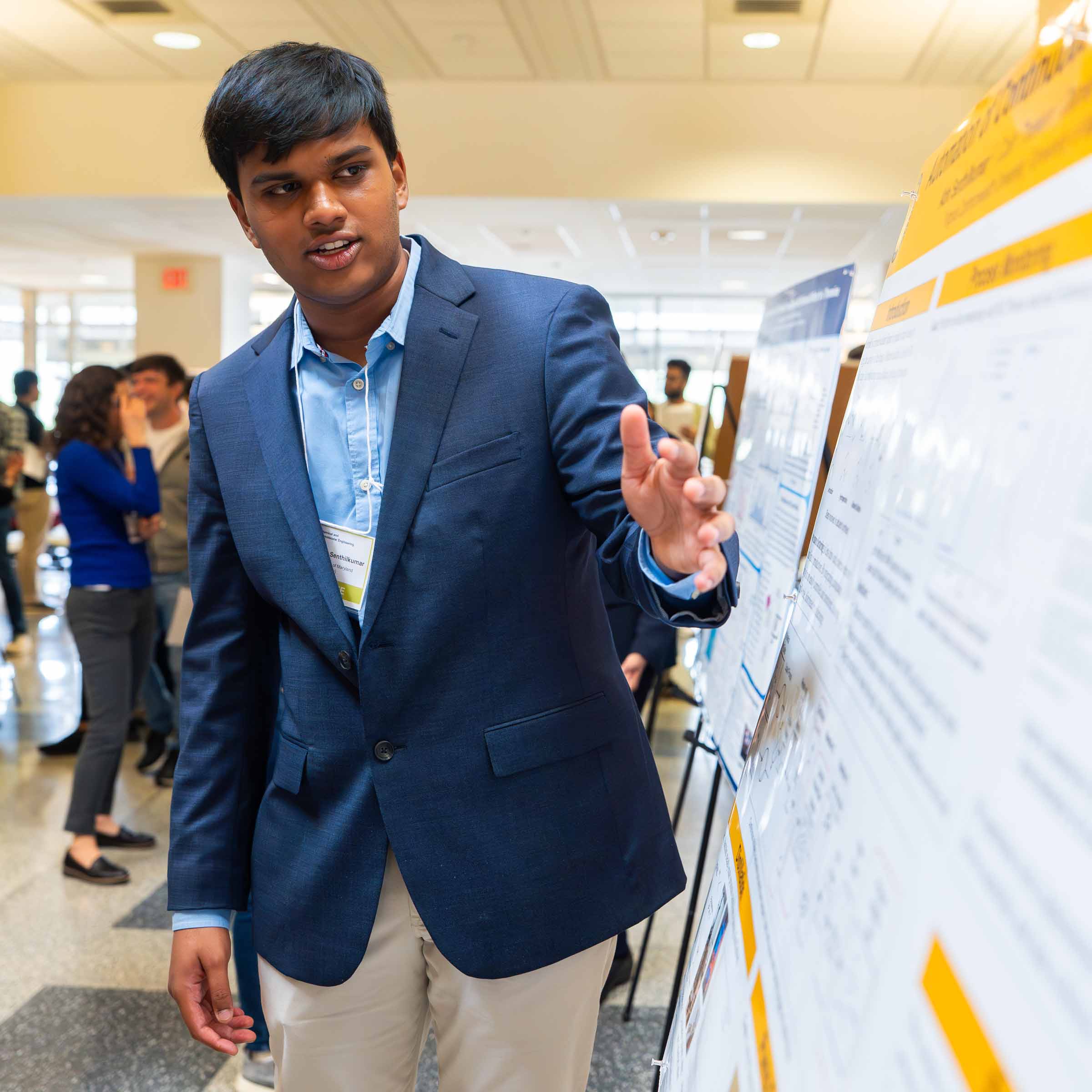

In a recent Nature Communications paper published by a team of University of Maryland engineers, a proposed artificial intelligence (AI) integrated platform circumvents conventional design processes to accomplish the design of stretchable electrodes in an automated fashion.

Research done by Po-Yen Chen, an assistant professor in the Department of Chemical and Biomolecular Engineering, in conjunction with Teng Li, a professor in the Department of Mechanical Engineering, led to the design of flexible electrodes that sustain functional performance and strain insensitivity, three feature requirements that have slowed progress in soft robotics and wearable technologies.

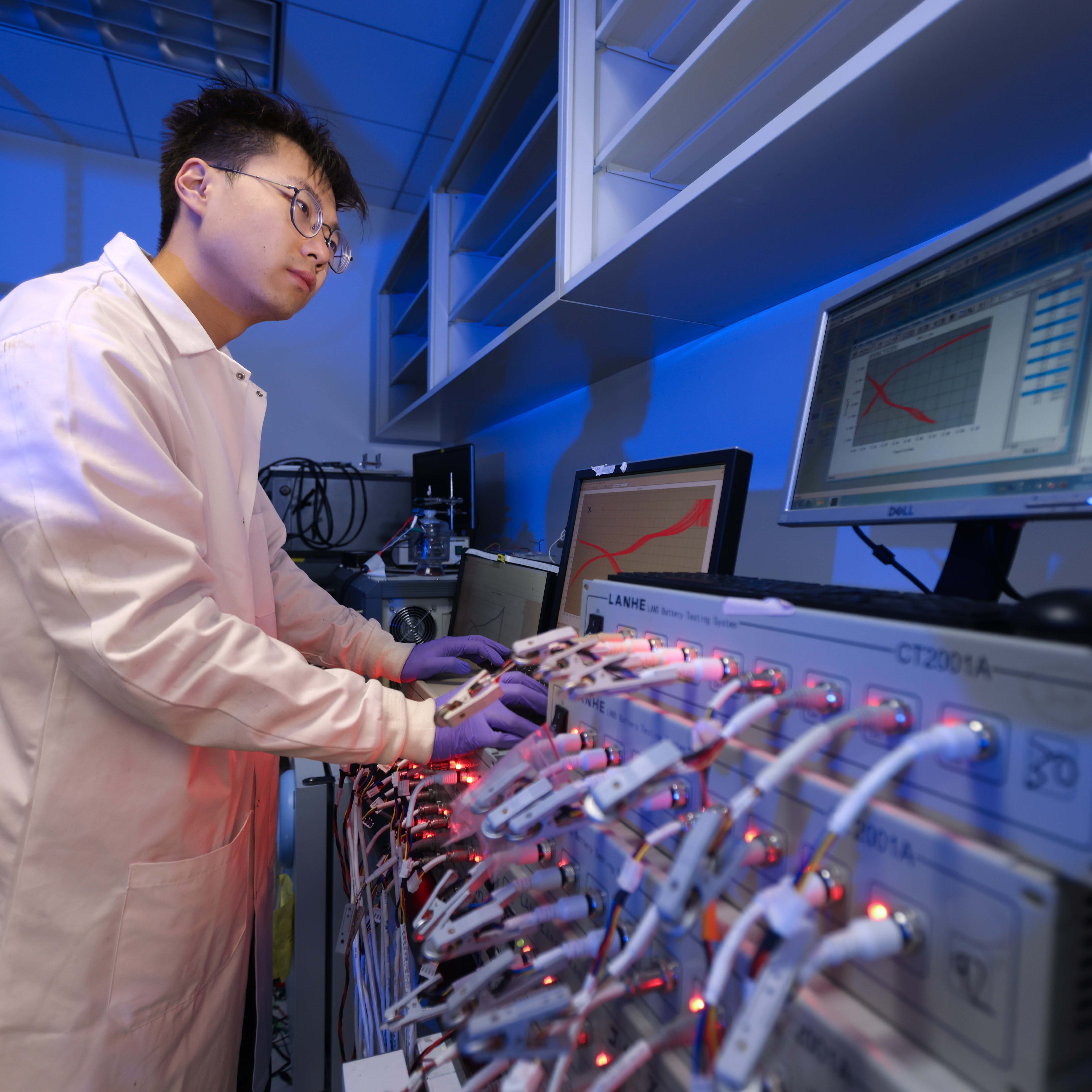

Consisting of robot-automated experimentation, machine learning predictions, and simulation tools, the innovative AI-led workflow shies away from conventional trial-and-error research processes that are often labor intensive and time consuming with the potential to aid new design challenges.

“This workflow is just the beginning; we envision this platform accelerating the development of a wide range of multifunctional materials, from soft robotics to advanced energy storage,” said Chen.

According to Chen’s findings, the AI-aided platform enabled the design of electrodes that could stretch over ten times their original length without losing conductivity, a highly desirable feature for modern electronic devices such as stretchable transistors, wearable and implantable sensors, and deformable energy storage devices.

Li’s group, whose role was focused on the mechanics of the electrodes, found that by controlling the micro-texture of the electrode’s conductive layers, they had forced the material to accommodate strain through geometric unfolding rather than fracturing, even when stretched to extreme limits.

“This mechanical resilience is the missing link for creating ‘unbreakable’ wearable tech and soft robotic skins that can endure impacts and complex twisting while transmitting high-fidelity data,” said Li.

Some of the long-term implications for stretchable electronics in the market are transferable to healthcare applications. More reliable wearable technologies could remain comfortable on the skin and reduce signal disruptions caused by the material’s bending and stretching.

Other applications for the deformable conductors could aid innovations in human-machine interfaces that move naturally with us, including rehabilitation devices, prosthetics, Augmented Reality (AR) and Virtual Reality gloves, and sports-performance wearables. Additionally, the electrodes could provide new platforms for soft robotics, allowing for stretchable electrical pathways that integrate sensing and actuation into soft, flexible structures.

“This capability can help robots interact more safely and effectively with people and the physical world," said Haochen Yang, the first author of the study and a doctoral student in chemical and biomolecular engineering.

Moving forward, the research team will focus on expanding the platform to jointly optimize formulation, microstructure, and processing conditions for diverse targets, such as mechanical and electrical performance for electronic devices, signal fidelity and durability for tactile sensors, and ionic conductivity with wide electrochemical stability windows for electrolytes. In parallel, the team will strengthen the AI-and robotics-integrated workflow with multi-objective active learning, a broader materials design space, and expanded automation capabilities, enabling faster identification of high-performing formulations and fabrication parameters.

Published February 3, 2026