News Story

Fisher Paper Among Top 25 "Hottest Articles"

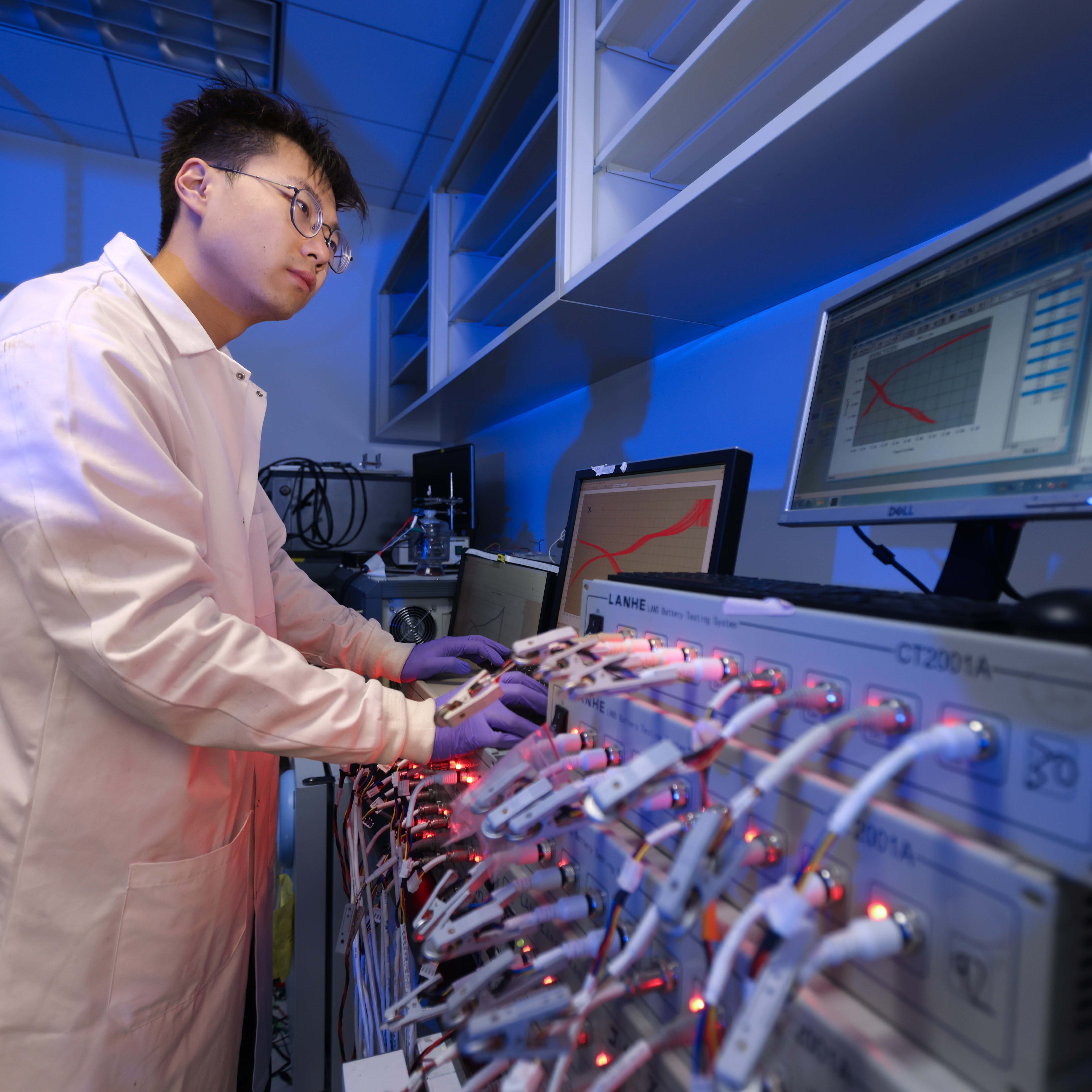

Research by a Department of Chemical and Biomolecular Engineering (ChBE) graduate student describing a solid polymer electrolyte for lithium ion batteries has earned a place among the Journal of Power Sources' "Hottest Articles" for the fourth quarter of 2011.

"Solid polymer electrolytes with sulfur based ionic liquid for lithium batteries," the first paper published by Aaron Fisher, was the 25th most downloaded from journal's web site between October and December. The journal has the highest impact factor among those covering the field of electrochemistry, which includes battery, fuel cell, and other energy research.

In the work, Fisher, advised by Professor Peter Kofinas (Fischell Department of Bioengineering), describes the electrochemical properties of a solid hybrid polymer electrolyte for lithium batteries made from tri-ethyl sulfonium bis(trifluorosulfonyl) imide (S2TFSI), lithium TFSI, and poly(ethylene oxide) (PEO).

Current lithium-ion batteries use a liquid electrolyte. Over time, the low boiling point of this liquid leads to electrolyte loss and decreased performance. For safety reasons, each battery must also be encased in several layers of packaging that separate its contents from both people and the environment, and limit internal vapor pressure to safe levels. Dendrite formation (branching crystal growth) in the liquid electrolyte leads to limited power cycling, which eventually short circuits the batteries.

Fisher's solid electrolyte addresses these problems in several ways. "We generally stress the safety of this product relative to lithium-ion batteries on the market," he explains. "My electrolyte replaces the current flammable solutions with polymer and an ionic liquid [a liquid salt]. These materials don't burn—they decompose—and they don't cause a buildup of internal pressure. The ionic liquid also boosts the conductivity of the polymer, so the battery can be used at lower temperatures."

The polymer electrolyte could also lead to more flexible battery designs—figuratively and literally. "Our current electrolytes limit battery architecture to simple shapes," says Fisher. "The ease of processing a polymer electrolyte would allow the production of thin film flexible batteries that could be wound into coils or processed as coatings and sheets."

For More Information:

See: Fisher, A.S.; Khalid, M.B.; Widstrom, M.; Kofinas, P. "Solid polymer electrolytes with sulfur based ionic liquid for lithium batteries," Journal of Power Sources, 196(2): 9767-9773 (2011). Online »

Published February 10, 2012