News Story

Choi, Lee Groups: Breakthroughs in Nanofibers

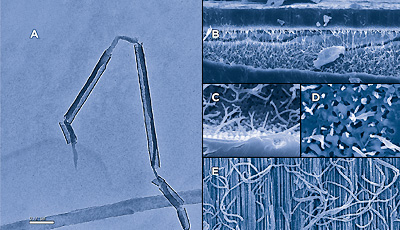

A: Transmission electron microscopy (TEM) image of a nanofiber inside a silica nanotube reactor. B: Scanning electron microscopy (SEM) image of the homemade membrane, pore diameter 60nm. C: SEM image, detail of B. D: SEM image of nanofibrils emerging from the pores, top view. E: SEM image of a side cross-sectional view of the pores.

The project originally focused on the manufacture syndiotactic polystyrene (sPS) nanofibers—a strong, lightweight, heat-resistant material that could be developed for use in electronics and other high-temperature processes—using a high activity metallocene catalyst, supported on a silica coated, porous anodized alumina film as a template. Each pore in the film serves as a tiny, rod-shaped reactor that extrudes a semicrystalline syndiotactic polystyrene nanofibril as it forms.

As work progressed the project produced three significant results: First, that the SNTR is highly effective in customizing polymer properties; second, the discovery by Ph.D. student Joong Jin Han (advised by Choi) that the sPS nanofibers synthesized in the reactor have an unusually high molecular weight, which should greatly enhance their strength and thermal resistance; and third, a means of isolating the silica tubes from the film substrate and using transmission electron microscopy to observe of the growth of the polymer nanofibrils inside the catalyst channels—the first time this has been accomplished.

The findings grew out of Choi and Lee's exploration of new techniques for polymer synthesis, the development of new polymers using nanotechnology and catalytic reaction engineering, and their desire to develop a better understanding of polymer growth mechanisms and structural properties.

The professors plan to continue their collaboration. According to Choi, the next step is to produce enough of the sPS nanofibers to test and define their physical, mechanical, and rheological properties. Currently the fibers are produced under very sensitive and controlled conditions, he adds, so if they show promise for industry, the next challenge will be to devise a way to easily mass-produce them.

A paper about the research, "Syndiotactic Polystyrene Nanofibrils in Silica Nanotube Reactors: Understanding of Synthesis with Ultrahigh Molecular Weight" was recently published in the Journal of the American Chemical Society, 2008, 130(12): 3920-3286.

Published May 8, 2008